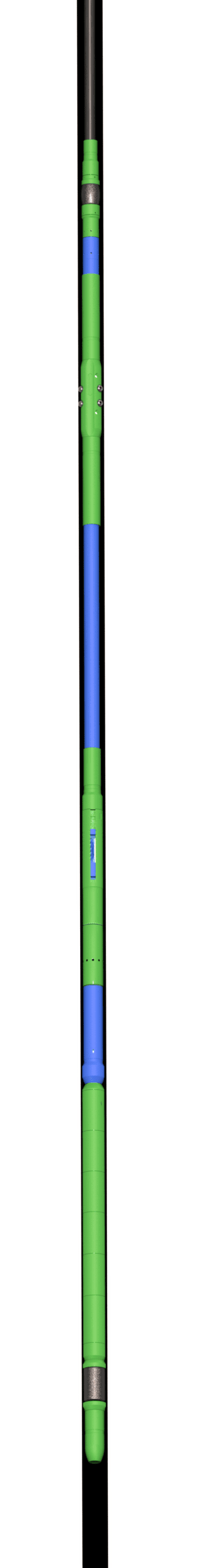

Used to create a choke point in the A-annulus to force the fluid flow path into the B-annulus for a more effective clean out

Impact vibration and jetting used to break up and dislodge stubborn cement or barite during washing

Hydro-Mechanical Perforator

expands to create the A B annulus cement supoprt barrier

OPERATION

The 2-trip system of Perf – Wash – and Cement has huge upside in creating a large flow area over a large distance to increase the chance of a successful wash and remedial cement job. On each cycle of the Gator perforator – 4 perforations are made simultaneously at 90 deg phasing. The perforation profile creates slots that direct fluid flow in a circular pattern up the B-annulus. The Jack hammer (washing tool) uses pistons to push out against the casing I.D that drop along the perf profile to create a jack hammer force. This helps agitate any cement or debris behind the casing in the B-annulus. Without having to trip tools to surface cement can be pumped and squeezed into the recent perforated and washed Gator perforations.

Run 1 Steps: Cut: Gator Perforating Operations

1. RIH to desired depth. Note: Wellbore fluid will by-pass through MPX

when RIH.

2. Move Gator into perforating position as per tubing tally.

3. Pressure up to specified pressure to activate MPX - shear release to

expand - set as A & B annuli plug. Gator will make its first cut

simultaneously.

4. Pressure up to specified pressure to shear the parting stem in MPX. This

disconnects the A & B annuli cement barrier (bridge plug) from the BHA.

5. Pull up to come out of the Gator Cut and move to the next position.

6. Flow at minimum specified rate to close the VCV (adjust accordingly).

7. Activate Gator perforator by pressuring up to max specified pressure or

until dump sub activates (Gator max stroke achieved)

8. Open ULS to equalize tubing to annulus by moving string into

compression.

9. Pick up and re-set Gator and repeat step #5-7 for more cuts

10. When finished cutting, POOH.

Run 2 Steps: Clean, Condition, Cement Operations

11. RIH to start position above top cuts.

12. Activate the JH by circulating at a specified rate. Continue movement

down-hole while circulating at a specified rate and rotational speed.

13. Reciprocate tubing string across perforating intervals. Repeat multiple

passes until returns are favorable (returns free of debris).

14. Stop pumping.

15. Position top diverter packer above bottom set of perfs and pump

cement spacer/conditioner bottoms up thru B annulus.

16. After specified spacer pumped away, pump cement at specified rate

while moving up-hole through the perforated interval.